Introduction

In this article, we will explore the CR40SS Stainless Steel Scraper Chain for Modular Conveyor Systems. This durable and high-quality chain is designed to enhance the performance and efficiency of conveyor systems in various industries. Let’s delve into the features, applications, advantages, troubleshooting, selection criteria, and the importance of Stainless Steel Sprockets for Scraper Chains.

Features of CR40SS Stainless Steel Scraper Chain

1. Corrosion Resistance: The CR40SS chain is made from high-grade stainless steel, providing excellent resistance against corrosion in challenging environments.

2. High Strength: The chain is designed to withstand heavy loads and maintain its integrity even in demanding applications.

3. Wear Resistance: With its robust construction, the CR40SS chain offers exceptional resistance to wear, ensuring a longer service life.

4. Easy Maintenance: The chain requires minimal maintenance, reducing downtime and increasing productivity.

5. Precision Engineering: The chain is manufactured with strict quality standards, ensuring precise dimensions and optimal performance.

Applications of CR40SS Stainless Steel Scraper Chain

The CR40SS Stainless Steel Scraper Chain finds wide applications in various industries, including:

1. Food Processing: The chain is suitable for conveying food products in processing plants, ensuring hygienic and efficient operations.

2. Chemical Industry: It is utilized in chemical manufacturing processes, where resistance to corrosive chemicals is vital.

3. Mining Operations: The chain is ideal for conveying materials in mining operations due to its durability and strength.

4. Waste Management: It is used in waste management facilities to move and process waste materials effectively.

5. Automotive Manufacturing: The chain is employed in assembly lines for transporting automotive components efficiently.

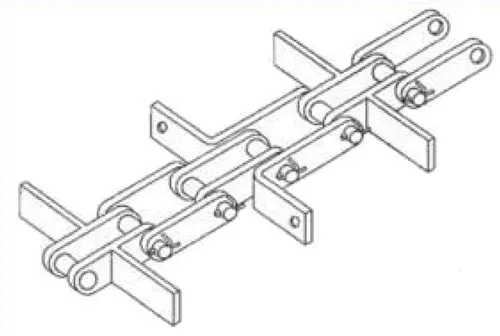

CR40SS Stainless Steel Scraper Chain in action:

Why Choose CR40SS Stainless Steel Scraper Chain for Modular Conveyor Systems?

The CR40SS Stainless Steel Scraper Chain offers numerous benefits and advantages in its designated applications:

1. Enhanced Durability: The chain’s stainless steel construction ensures long-lasting performance, even in harsh environments.

2. Improved Efficiency: With its smooth operation and reliable design, the chain enhances the overall efficiency of conveyor systems.

3. Optimal Performance: The chain’s wear resistance and high strength enable it to handle heavy loads and maintain performance over time.

4. Cost-Effective: By minimizing maintenance requirements and reducing downtime, the chain proves to be a cost-effective solution.

5. Versatility: The CR40SS chain can be customized to meet specific requirements, making it suitable for a wide range of applications.

Common Faults, Diagnosis, and Maintenance for CR40SS Stainless Steel Scraper Chain

1. Faults:

- Chain Misalignment

- Inadequate Lubrication

- Excessive Wear

- Chain Elongation

2. Diagnosis:

- Inspect chain alignment regularly

- Monitor lubrication levels and apply lubricant as recommended

- Check for signs of excessive wear, such as elongation or damaged links

- Measure chain length to detect elongation

3. Maintenance and Replacement:

- Realign the chain if misalignment is detected

- Ensure proper lubrication to prevent wear and extend chain life

- Replace worn or damaged sections of the chain promptly

- Regularly inspect and measure chain length to identify elongation and plan for replacement

Selecting and Customizing the Perfect Stainless Steel Scraper Chain

When choosing or customizing a stainless steel scraper chain, several parameters and practical conditions should be considered:

- Working Environment: Analyze the temperature, humidity, and chemical exposure of the application environment.

- Load Capacity: Determine the maximum load the chain needs to withstand to ensure optimal performance.

- Speed and Efficiency: Consider the desired speed and efficiency requirements for the conveyor system.

- Chain Size and Pitch: Select the appropriate chain size and pitch based on the specific conveyor system design.

- Additional Features: Assess the need for specialized features such as attachments, extended pins, or surface coatings.

Stainless Steel Sprockets for Scraper Chains

Stainless Steel Sprockets and Scraper Chains are complementary components in conveyor systems, working together to ensure smooth and efficient operation. The sprockets provide the necessary drive and control for the chains, facilitating the movement of materials. Our company offers a range of stainless steel sprockets compatible with the CR40SS Stainless Steel Scraper Chain.

We understand the importance of high-quality scraper chains, and that’s why we recommend our premium CR40SS Stainless Steel Scraper Chain. Our products and company have the following advantages:

1. Superior Quality: Our scraper chains are manufactured using top-grade materials and advanced production techniques to ensure exceptional quality and performance.

2. Customization Options: We offer customized solutions to meet specific application requirements, providing tailored scraper chains for various industries.

3. Competitive Pricing: Our products are competitively priced without compromising on quality, offering excellent value for money.

4. Prompt Customer Support: Our dedicated customer support team is always ready to assist with any inquiries, ensuring a smooth purchasing experience.

5. Encouraging Customer Exploration: We encourage customers to explore the benefits and applications of our stainless steel scraper chains and invite them to contact us for their purchasing needs.

Q&A about CR40SS Stainless Steel Scraper Chain

Q: What is the maximum temperature resistance of the CR40SS Stainless Steel Scraper Chain?

A: The CR40SS chain can withstand temperatures up to 600 degrees Celsius, making it suitable for high-temperature applications.

Q: Can the CR40SS Stainless Steel Scraper Chain be used in wet environments?

A: Yes, the chain is designed to resist corrosion and can be used in wet or humid environments without compromising its performance.

Q: How often should the CR40SS Stainless Steel Scraper Chain be lubricated?

A: Lubrication frequency depends on various factors, such as the application conditions and load. However, regular lubrication every 500 to 1,000 operating hours is recommended.

Edited by Zqq.