Introduction

In small-scale mining operations, the CR40SS stainless steel scraper chain plays a crucial role in ensuring efficient and effective material conveying. This article will delve into the various aspects of this chain and its applications in the mining industry.

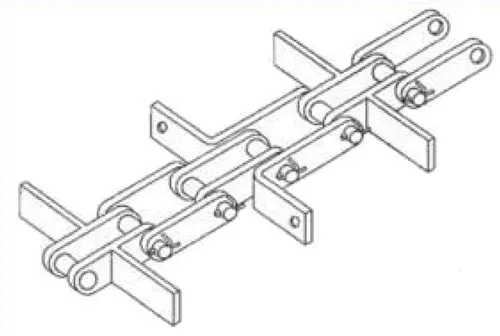

Chain Structure and Components

The CR40SS stainless steel scraper chain is comprised of several components, including:

- Scraper Plates: These plates are attached to the chain and are responsible for moving material along the conveyor.

- Link Pins: These pins connect the scraper plates, allowing for smooth movement.

- Main Link Plates: These plates provide support and rigidity to the chain.

- Wear Strips: These strips reduce friction and wear between the scraper plates and the conveyor surface.

The chain structure ensures durability and optimal performance in demanding mining conditions.

Applications of CR40SS Stainless Steel Scraper Chain

The CR40SS stainless steel scraper chain finds extensive use in small-scale mining operations due to its exceptional characteristics. Some key applications include:

- Material Conveying: The chain excels at transporting various materials, including coal, ore, and minerals, across different mining sites.

- Scraper Chain Conveyors: These conveyors utilize the CR40SS chain to efficiently move bulk materials over long distances, reducing manual labor.

- Apron Feeders: The scraper chain ensures smooth and reliable material feeding in apron feeder systems.

- Drag Conveyors: The chain’s robust design enables it to withstand heavy loads and resist abrasive materials commonly encountered in drag conveyor applications.

The CR40SS stainless steel scraper chain’s versatility makes it indispensable in small-scale mining operations.

Why Choose CR40SS Stainless Steel Scraper Chain for Small-Scale Mining Operations

The CR40SS stainless steel scraper chain offers several advantages that make it an ideal choice for small-scale mining operations:

- Exceptional Corrosion Resistance: The stainless steel construction ensures prolonged durability and resistance to corrosion, even in harsh mining environments.

- High Tensile Strength: The chain’s high tensile strength allows it to withstand heavy loads and intense operating conditions.

- Low Maintenance: The chain’s robust design minimizes the need for frequent maintenance, reducing downtime and overall costs.

- Smooth Operation: The well-engineered chain structure ensures smooth and reliable material conveying, optimizing mining operations.

- Customizable Options: The CR40SS chain can be tailored to specific mining requirements, with options for different lengths and attachments.

Common Faults, Troubleshooting, and Maintenance

Despite its durability, the CR40SS stainless steel scraper chain may encounter certain faults during operation. Here are some common faults, along with troubleshooting steps and maintenance recommendations:

- Fault: Excessive Chain Wear

- Fault: Chain Alignment Issues

- Fault: Chain Breakage

Diagnosis: Inspect the scraper plates and wear strips for signs of excessive wear. Check for misalignment or insufficient lubrication.

Repair/Replacement: Replace worn scraper plates and wear strips. Ensure proper lubrication of the chain.

Diagnosis: Examine the chain’s alignment on the conveyor. Look for any obstructions or misalignment that may hinder smooth operation.

Repair/Replacement: Adjust the chain’s alignment as necessary. Remove any obstructions that may impede proper movement.

Diagnosis: Inspect the chain for any signs of damage, such as broken links or pins.

Repair/Replacement: Replace the damaged chain sections or links. Ensure all connections are secure and properly lubricated.

Choosing and Customizing the Ideal Stainless Steel Scraper Chain

When selecting or customizing a stainless steel scraper chain, several parameters and real-life conditions need to be considered:

- Operating Environment: Evaluate the temperature range, moisture levels, and exposure to corrosive substances in the mining environment.

- Material Compatibility: Ensure the chain material is suitable for handling the specific mining materials.

- Chain Size and Load Capacity: Determine the appropriate chain size and load capacity to meet the operational requirements.

- Lubrication Requirements: Consider the lubrication needs of the chain to maintain optimal performance and longevity.

- Installation and Maintenance Ease: Choose a chain that is easy to install, inspect, and maintain, minimizing downtime.

Stainless Steel Sprockets for Scraper Chains

The CR40SS stainless steel scraper chain and stainless steel sprockets complement each other, forming a crucial combination for efficient mining operations. The sprockets provide the necessary rotational force to drive the scraper chain, ensuring smooth material conveying.

Our company offers a range of stainless steel sprockets that are specifically designed to match the CR40SS scraper chain. These sprockets are engineered for durability, precision, and optimal performance. By choosing our products, you can ensure a seamless integration of the scraper chain and sprockets, resulting in enhanced productivity and prolonged equipment life.

Recommendation and Company Advantages

We highly recommend our CR40SS stainless steel scraper chains for small-scale mining operations. When you choose our products, you benefit from:

- Superior Quality: Our scraper chains are manufactured using high-grade stainless steel, ensuring exceptional durability and performance.

- Customization Options: We offer flexible customization options to meet your specific mining requirements.

- Expertise and Experience: With years of experience in the industry, we have the knowledge and expertise to provide reliable solutions.

- Competitive Pricing: Our products offer excellent value for money, helping you optimize your mining operations while staying cost-effective.

- Customer Support: Our dedicated customer support team is available to assist you with any inquiries or concerns.

Explore the benefits of our stainless steel scraper chains and contact us today to make a purchase.

Q&A

Q: Can the CR40SS stainless steel scraper chain be used in underground mining operations?

A: Yes, the CR40SS chain is suitable for both surface and underground mining operations. Its corrosion resistance and durability make it well-suited for challenging underground environments.

Q: Are replacement parts readily available for the CR40SS stainless steel scraper chain?

A: Yes, our company provides a comprehensive range of replacement parts for the CR40SS scraper chain, ensuring minimal downtime in case of any component failures.

Q: Can the CR40SS chain be used in high-temperature mining applications?

A: While the CR40SS chain exhibits good heat resistance, it is important to consider the specific temperature range and consult with our experts to ensure suitability for high-temperature mining applications.

Edited by Zqq.