Introduction

This blog post aims to provide comprehensive information on the FV112SS Stainless Steel Scraper Chain for Industrial Composting Facilities. Throughout the article, we will explore the various aspects and applications of this chain, highlighting its unique features and benefits.

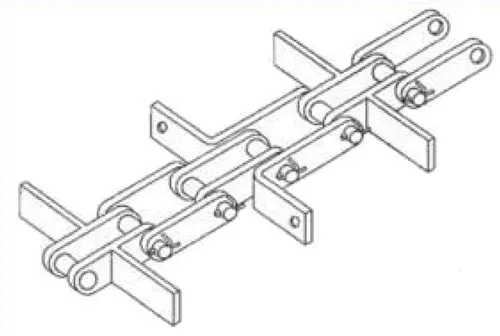

1. The Structure and Composition of FV112SS Stainless Steel Scraper Chain

The FV112SS Stainless Steel Scraper Chain is composed of high-quality stainless steel, ensuring durability and resistance to corrosion. Its structure consists of interconnected links forming a continuous chain loop.

2. Applications of FV112SS Stainless Steel Scraper Chain

The FV112SS Stainless Steel Scraper Chain finds extensive use in industrial composting facilities. It is primarily employed in the following applications:

- Conveying organic waste materials

- Distributing compost and fertilizer

- Transporting biomass

These applications require a reliable and robust chain that can withstand heavy loads and harsh environments.

Why Choose FV112SS Stainless Steel Scraper Chain for Industrial Composting Facilities?

The FV112SS Stainless Steel Scraper Chain offers several advantages that make it the ideal choice for industrial composting facilities:

- 1. Exceptional strength and durability: With its stainless steel construction, the chain can withstand heavy loads and resist corrosion, ensuring a long service life.

- 2. Precision engineering: The chain is precisely engineered to provide smooth and efficient operation, minimizing downtime and enhancing productivity.

- 3. Low maintenance requirements: The chain’s robust design and high-quality materials reduce the need for frequent maintenance, saving time and costs.

- 4. Enhanced safety features: The chain incorporates safety measures such as lubrication points and protective covers, ensuring safe operation and minimizing the risk of accidents.

- 5. Versatile compatibility: The FV112SS Stainless Steel Scraper Chain is compatible with various types of machinery and can be easily integrated into existing systems.

Common Issues, Diagnosis, and Maintenance of FV112SS Stainless Steel Scraper Chain

Despite its exceptional durability, the FV112SS Stainless Steel Scraper Chain may encounter certain issues in industrial composting facilities. Here are some common problems:

- 1. Chain elongation: Over time, the chain may experience elongation due to wear and tear. Regular inspection and adjustment can help mitigate this issue.

- 2. Contamination and build-up: The chain may accumulate debris and organic matter, leading to reduced efficiency. Proper cleaning and lubrication are essential to prevent this problem.

- 3. Misalignment: Improper alignment can cause the chain to deviate from its intended path. Regular alignment checks and adjustments are crucial to maintain smooth operation.

Upon encountering these issues, the following steps can be taken for diagnosis and maintenance:

- 1. Visual inspection: Examine the chain for any signs of damage, wear, or misalignment.

- 2. Lubrication: Ensure proper lubrication of the chain to minimize friction and prevent premature wear.

- 3. Cleaning: Regularly clean the chain to remove debris and prevent the build-up of contaminants.

- 4. Tension adjustment: Check the chain’s tension and make necessary adjustments to maintain optimal performance.

Choosing and Customizing the Right FV112SS Stainless Steel Scraper Chain

When selecting or customizing a suitable FV112SS Stainless Steel Scraper Chain, several parameters and practical conditions need to be considered:

- 1. Load capacity: Determine the maximum load the chain needs to bear to ensure it can withstand the required weight.

- 2. Speed requirements: Consider the desired speed of the chain to ensure efficient operation and productivity.

- 3. Environmental factors: Evaluate the operating environment, including temperature, moisture, and corrosive substances, to choose the appropriate stainless steel grade.

- 4. Chain configuration: Select the suitable pitch, width, and number of teeth to match the specific application and machinery.

Stainless Steel Sprockets for Scraper Chains

The FV112SS Stainless Steel Scraper Chain and Stainless Steel Sprockets form a complementary relationship, with each playing a vital role in the overall performance of the system. The sprockets are specially designed to interact with the scraper chain, ensuring smooth engagement and efficient power transmission.

Our company offers a range of compatible sprockets suitable for the FV112SS Stainless Steel Scraper Chain. These sprockets are manufactured with precision to deliver reliable performance and long-lasting durability.

Recommendation and Company Advantages

We highly recommend our FV112SS Stainless Steel Scraper Chains for industrial composting facilities. Here are five reasons why:

- 1. Exceptional quality: Our scraper chains are manufactured using high-grade stainless steel, ensuring superior strength and durability.

- 2. Customization options: We offer the flexibility to customize the chain to meet specific requirements, ensuring optimal performance in any application.

- 3. Expertise and support: Our team of professionals has extensive knowledge and experience in scraper chain systems, providing comprehensive technical support.

- 4. Timely delivery: We understand the importance of prompt delivery and strive to ensure your orders reach you on time.

- 5. Customer satisfaction: We prioritize customer satisfaction and are committed to providing exceptional products and services.

We encourage you to explore our FV112SS Stainless Steel Scraper Chains and contact us for any inquiries or purchases.

Q&A

Q1: How often should the FV112SS Stainless Steel Scraper Chain be lubricated?

A1: The lubrication frequency depends on the operating conditions and the manufacturer’s recommendations. However, as a general guideline, we recommend lubricating the chain every 100-200 operating hours or as needed based on regular inspection.

Q2: Can the FV112SS Stainless Steel Scraper Chain be used in high-temperature environments?

A2: Yes, the FV112SS Stainless Steel Scraper Chain is designed to withstand high temperatures. However, it is essential to choose the appropriate stainless steel grade based on the specific temperature range and other environmental factors.

Q3: Can the FV112SS Stainless Steel Scraper Chain be used in wet or corrosive conditions?

A3: Absolutely. The chain’s stainless steel construction ensures excellent resistance to corrosion and moisture, making it suitable for wet and corrosive environments encountered in industrial composting facilities.

Edited by Zqq