1. Introduction

In this blog post, we will explore the FV112SS Stainless Steel Scraper Chain for Intensive Livestock Feeding Systems and its various applications. We will delve into the features and benefits of this chain, providing a comprehensive understanding of its usage in the industry.

2. Understanding the FV112SS Stainless Steel Scraper Chain

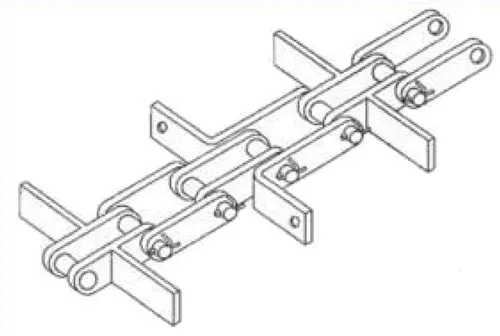

The FV112SS Stainless Steel Scraper Chain is a crucial component in intensive livestock feeding systems. Its unique design and superior quality make it an ideal choice for various agricultural applications.

2.1 Chain Structure

The FV112SS Stainless Steel Scraper Chain features a durable and robust structure. It consists of high-quality stainless steel links that are designed to withstand harsh working conditions.

2.2 Application in Livestock Feeding Systems

This chain is specifically engineered for intensive livestock feeding systems, where it plays a vital role in ensuring efficient feed distribution. It is commonly used in automated feeding machines and conveyor systems.

Why Choose the FV112SS Stainless Steel Scraper Chain for Livestock Feeding Systems

The FV112SS Stainless Steel Scraper Chain offers several advantages that make it highly suitable for livestock feeding systems. Let’s explore the reasons why this chain is the preferred choice in the industry:

1. Excellent Corrosion Resistance

Due to its stainless steel construction, this chain exhibits exceptional resistance to corrosion caused by feed and harsh cleaning agents. It ensures longevity and reliability in demanding environments.

2. High Strength and Load Capacity

The FV112SS Stainless Steel Scraper Chain is designed to handle heavy loads and withstand the rigors of intensive feeding systems. Its robust structure provides the necessary strength and durability.

3. Smooth and Silent Operation

This chain operates smoothly and quietly, minimizing disturbances in the livestock feeding process. It ensures a stress-free environment for animals and enhances overall efficiency.

4. Easy Maintenance and Cleaning

The stainless steel construction of this chain allows for easy cleaning and maintenance. It can withstand frequent washdowns, ensuring hygienic feeding systems and reducing downtime.

5. Customization Options

We offer customization options for the FV112SS Stainless Steel Scraper Chain to meet specific requirements of different livestock feeding systems. Our experienced team can assist in tailoring the chain to your unique needs.

Common Faults, Troubleshooting Steps, and Maintenance Recommendations

1. Chain Misalignment

If the scraper chain appears misaligned, check for any obstructions or improper tension. Adjust the tension and ensure the chain is aligned correctly with the sprockets.

2. Excessive Wear

Examine the chain for signs of excessive wear, such as elongated links or worn-out surfaces. If significant wear is observed, consider replacing the chain to maintain optimal performance.

3. Lack of Lubrication

Inadequate lubrication can cause increased friction and premature wear. Regularly inspect the chain’s lubrication levels and apply appropriate lubricants as recommended by the manufacturer.

4. Broken or Damaged Links

If any links are broken or damaged, it is crucial to replace them immediately to maintain the integrity of the chain. Ignoring damaged links may lead to chain failure and costly downtime.

5. Regular Cleaning and Inspection

To ensure optimal performance, regularly clean the chain and inspect it for any signs of damage or wear. Promptly address any issues to prevent further damage and extend the chain’s lifespan.

Choosing and Customizing the Right Stainless Steel Scraper Chain

1. Consider Operating Conditions

Take into account factors like temperature, humidity, and exposure to chemicals. Select a stainless steel scraper chain that can withstand the specific conditions of your livestock feeding system.

2. Determine Load Requirements

Assess the load capacity needed for your application. Consider the weight of the feed and any additional stresses or forces that the chain will experience during operation.

3. Evaluate Chain Pitch and Length

Choose the appropriate chain pitch and length based on the configuration of your feeding system. Ensure the chain fits correctly and provides optimal performance.

4. Seek Professional Guidance

If you are unsure about the selection process or require customization, consult with industry experts or the manufacturer. They can provide valuable insights and recommend the best options for your specific needs.

Stainless Steel Sprockets for Scraper Chains

The FV112SS Stainless Steel Scraper Chain works in tandem with stainless steel sprockets to ensure smooth and efficient operation. The sprockets are designed to precisely engage with the chain, facilitating seamless movement and accurate feed distribution.

Our company offers a range of stainless steel sprockets specifically manufactured to complement the FV112SS Scraper Chain. These sprockets are engineered for durability and high performance in intensive livestock feeding systems.

We take pride in providing a comprehensive solution for your livestock feeding system. Our company offers compatible sprockets that perfectly match the FV112SS Scraper Chain, ensuring optimal performance and longevity.

Recommendation and Company Advantages

We highly recommend our FV112SS Stainless Steel Scraper Chain for your intensive livestock feeding systems. Here are some reasons to choose our products:

1. Superior Quality

Our stainless steel scraper chains are manufactured using high-quality materials and advanced production techniques. We ensure that each chain meets stringent quality standards to provide reliable performance.

2. Customization Options

We understand that every livestock feeding system is unique. Hence, we offer customization options to tailor our chains to your specific requirements, ensuring optimal functionality and efficiency.

3. Expertise and Experience

With years of experience in the industry, our team consists of experts who possess extensive knowledge about scraper chains and intensive livestock feeding systems. We are committed to providing reliable solutions and excellent customer service.

4. Competitive Pricing

We offer our stainless steel scraper chains at competitive prices without compromising on quality. Our aim is to provide cost-effective solutions that deliver exceptional value for your investment.

5. Customer Satisfaction

Customer satisfaction is our top priority. We strive to exceed your expectations by delivering top-notch products and providing prompt assistance. We encourage you to explore our stainless steel scraper chains and contact us for further information or to make a purchase.

Q&A Section

Q: Can the FV112SS Stainless Steel Scraper Chain be used in other industries apart from livestock feeding systems?

A: While the FV112SS Stainless Steel Scraper Chain is primarily designed for intensive livestock feeding systems, it can also be utilized in other applications that require a durable and corrosion-resistant conveyor chain.

Q: What maintenance precautions should be taken for the FV112SS Stainless Steel Scraper Chain?

A: Regular cleaning, lubrication, and inspection are essential for maintaining the performance and longevity of the FV112SS Stainless Steel Scraper Chain. Ensure that the chain is free from debris and properly lubricated as per the manufacturer’s recommendations.

Q: Are spare parts available for the FV112SS Stainless Steel Scraper Chain?

A: Yes, we provide a wide range of spare parts for the FV112SS Stainless Steel Scraper Chain. These include replacement links, pins, and other components that may be required for maintenance or repair purposes.

Edited by Zqq.