Introduction

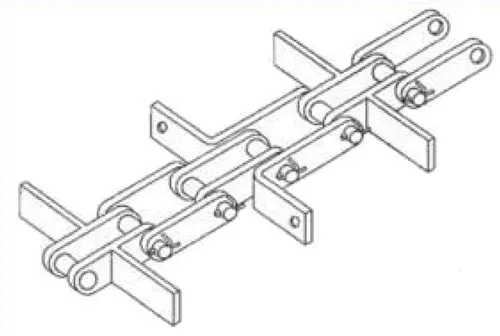

The FV112SS stainless steel scraper chain is a crucial component used in power station ash handling systems. This chain is specifically designed to handle the demanding conditions of power stations, offering durability and reliability. In this article, we will explore the various aspects of the FV112SS stainless steel scraper chain and its application in power station ash handling.

1. The Importance of Stainless Steel Scraper Chains in Power Station Ash Handling

Power station ash handling systems play a critical role in managing the byproducts generated during power generation. The FV112SS stainless steel scraper chain is an essential part of this system, ensuring the efficient and smooth movement of ash from the power station to disposal or recycling facilities. By using a stainless steel scraper chain, power stations can effectively handle large quantities of ash without compromising the integrity of the chain.

1.1 The Functionality of FV112SS Stainless Steel Scraper Chains

The FV112SS stainless steel scraper chain is specifically designed to withstand the harsh conditions of power station ash handling. Its robust construction and corrosion-resistant properties allow it to operate reliably in high-temperature environments and resist the corrosive nature of ash and other contaminants. Additionally, the scraper chain’s precise engineering ensures optimal performance and minimal maintenance requirements.

1.2 Applications of FV112SS Stainless Steel Scraper Chains

The FV112SS stainless steel scraper chain finds extensive use in various power station ash handling applications, including:

- Ash removal from boiler hoppers

- Ash transport in conveyor systems

- Clinker handling

- Bottom ash extraction

Each of these applications requires a reliable and durable chain that can withstand the demanding conditions of power station ash handling.

Why Choose FV112SS Stainless Steel Scraper Chain for Power Station Ash Handling

The FV112SS stainless steel scraper chain offers several advantages that make it the ideal choice for power station ash handling applications:

- Exceptional Corrosion Resistance: The stainless steel construction of the chain ensures excellent resistance to corrosion and degradation caused by ash and other contaminants.

- High Temperature Resistance: The FV112SS scraper chain is designed to withstand high temperatures commonly encountered in power stations, ensuring reliable performance even in extreme conditions.

- Low Maintenance: Thanks to its durable construction and precise engineering, the scraper chain requires minimal maintenance, reducing downtime and operational costs.

- Longevity: The FV112SS stainless steel scraper chain is built to last, providing extended service life and ensuring uninterrupted ash handling operations.

- Optimal Performance: The scraper chain’s precise design and engineering result in smooth and efficient ash handling, improving overall system performance.

Common Faults Analysis, Diagnostic Steps, and Maintenance Recommendations

While the FV112SS stainless steel scraper chain is highly durable, certain faults may occur over time due to wear and tear or operational issues. Here are some common faults, diagnostic steps, and maintenance recommendations:

- Fault: Chain Elongation

- Fault: Chain Jamming

- Fault: Chain Link Breakage

Diagnostic Steps: Check for excessive wear, misalignment, or insufficient tension.

Maintenance Recommendations: Regularly inspect and adjust tension, replace worn-out or damaged chain links, and ensure proper alignment.

Diagnostic Steps: Inspect for foreign objects or excessive buildup of ash or debris.

Maintenance Recommendations: Clean the chain thoroughly, remove any obstructions, and ensure proper lubrication.

Diagnostic Steps: Check for signs of fatigue, corrosion, or excessive load.

Maintenance Recommendations: Replace broken or damaged chain links promptly, inspect for underlying causes of excessive load, and consider reinforcement if necessary.

Choosing and Customizing the Right Stainless Steel Scraper Chain

When selecting or customizing a stainless steel scraper chain for your specific application, consider the following parameters and real-world conditions:

- Operating Temperature: Determine the maximum temperature the chain will encounter to ensure it can withstand the heat.

- Load Capacity: Evaluate the expected load and select a chain with suitable strength and capacity.

- Chain Speed: Consider the required speed of the chain and choose one that can handle the desired velocity without compromising performance.

- Material Selection: Assess the corrosive nature of the environment and select a stainless steel grade that offers adequate resistance.

- Environmental Factors: Take into account the presence of dust, moisture, or other contaminants that may affect chain performance.

Stainless Steel Sprockets for Scraper Chains

The FV112SS stainless steel scraper chain and stainless steel sprockets are complementary components in power station ash handling systems. The sprockets provide the necessary drive and guidance for the scraper chain, ensuring smooth and efficient operation. Our company offers compatible stainless steel sprockets that are designed specifically for use with the FV112SS scraper chain, guaranteeing optimal performance and compatibility.

Why Choose Our Stainless Steel Scraper Chains?

Our stainless steel scraper chains offer superior quality and numerous advantages for power station ash handling applications:

- Durable Construction: Our chains are built to withstand the demanding conditions of power station ash handling, ensuring long-lasting performance.

- Corrosion Resistance: The stainless steel material provides excellent resistance to corrosion and degradation, extending the service life of the chain.

- Customization Options: We offer customization services to tailor the chain’s specifications to your specific application, ensuring optimal performance.

- Reliable Service: Our company is committed to providing exceptional customer service, prompt delivery, and technical support.

- Cost-Effective Solution: Our stainless steel scraper chains offer a cost-effective solution by minimizing maintenance requirements and maximizing operational efficiency.

Q&A Section

Q1: Can the FV112SS stainless steel scraper chain be used in other industries apart from power station ash handling?

A1: While the FV112SS scraper chain is specifically designed for power station ash handling, its superior properties make it suitable for other applications that require corrosion-resistant and durable chains. However, it is recommended to consult with our experts for proper chain selection and customization.

Q2: How often should the FV112SS stainless steel scraper chain be lubricated?

A2: The lubrication frequency depends on various factors such as operating conditions, chain speed, and load. Regular inspections should be carried out to assess the lubrication requirements and ensure optimal performance. Consult the chain manufacturer’s guidelines for specific lubrication recommendations.

Q3: Can the FV112SS stainless steel scraper chain be repaired if it gets damaged?

A3: In some cases, minor repairs can be performed on the scraper chain, such as replacing individual links or repairing minor damages. However, it is generally recommended to replace the damaged chain with a new one to ensure optimal performance and reliability.

Edited by Zqq.