Introduction

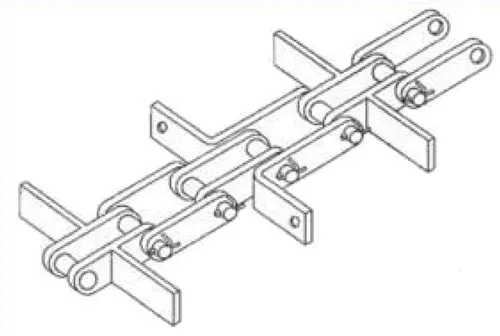

The FV140SS Stainless Steel Scraper Chain is a highly durable and efficient chain specifically designed for construction material handling. It is widely used in various applications due to its superior performance and reliability.

Advantages of FV140SS Stainless Steel Scraper Chain:

- High tensile strength and corrosion resistance: The FV140SS chain is made of high-quality stainless steel, which ensures its ability to withstand heavy loads and harsh environments.

- Smooth operation and minimal maintenance: The chain’s design and material composition reduce friction, resulting in smooth operation and minimal maintenance requirements.

- Enhanced safety features: The FV140SS chain is equipped with safety features such as anti-slip properties and high heat resistance, ensuring a safe working environment.

- Long service life: Thanks to its robust construction and high-quality materials, the FV140SS chain offers a long service life, reducing the need for frequent replacements.

- Versatile applications: The chain is suitable for a wide range of construction material handling applications, including conveyor systems, material elevators, and more.

Common Fault Analysis, Diagnosis, and Maintenance of FV140SS Stainless Steel Scraper Chain

The FV140SS Stainless Steel Scraper Chain, like any other mechanical component, may experience certain faults during operation. Here are some common fault scenarios, diagnostic steps, and maintenance recommendations:

- Fault: Chain elongation

- Fault: Chain jamming

- Fault: Chain corrosion

Diagnostic steps: Check for excessive wear on the chain links and sprockets. Measure the chain’s pitch length to determine if it has elongated beyond the recommended tolerance.

Maintenance recommendation: Replace the elongated chain links and sprockets with new ones to ensure proper functioning and prevent further damage.

Diagnostic steps: Inspect the chain for any foreign objects or debris that may be causing the jamming. Check the alignment of the chain and sprockets.

Maintenance recommendation: Remove any obstructions and ensure proper alignment of the chain and sprockets. Lubricate the chain if necessary to improve its performance.

Diagnostic steps: Examine the chain for signs of rust or corrosion. Determine the cause of corrosion, such as exposure to moisture or chemicals.

Maintenance recommendation: Clean the chain thoroughly and apply anti-corrosion coatings or lubricants to protect it from further corrosion. Regularly inspect and maintain the chain to prevent future corrosion.

Choosing and Customizing the Perfect Stainless Steel Scraper Chain

When selecting or customizing a stainless steel scraper chain, several parameters and practical considerations need to be taken into account:

- Load capacity: Determine the maximum load the chain will be subjected to in your specific application.

- Operating environment: Consider the temperature, humidity, and presence of corrosive substances in the operating environment.

- Chain pitch and width: Select the appropriate chain pitch and width based on your equipment’s requirements.

- Attachment type: Choose the suitable attachment type for your application, such as extended pins or flights.

- Customization options: If standard chains do not meet your needs, inquire about customization options such as special coatings or materials.

Stainless Steel Sprockets for Scraper Chains

The FV140SS Stainless Steel Scraper Chain and stainless steel sprockets are complementary components that work together to ensure efficient material handling. The sprockets are specifically designed to match the FV140SS chain and provide optimum performance.

Our company offers a wide range of stainless steel sprockets that are compatible with the FV140SS Stainless Steel Scraper Chain. These sprockets are made of high-quality materials and undergo rigorous quality control to ensure their reliability and durability.

Recommendation and Company Advantages

We highly recommend our FV140SS Stainless Steel Scraper Chains for your construction material handling needs. Here are the advantages of choosing our product:

- Superior quality: Our chains are manufactured using the highest quality stainless steel, guaranteeing their durability and performance.

- Customization options: We offer customization services to meet your specific requirements, ensuring a perfect fit for your application.

- Competitive pricing: Our chains are competitively priced, offering excellent value for money.

- Reliable customer support: Our dedicated customer support team is available to assist you with any inquiries or concerns regarding our products.

- Fast and efficient delivery: We prioritize prompt delivery to ensure your construction projects stay on schedule.

We encourage you to explore our FV140SS Stainless Steel Scraper Chains and contact us for purchasing inquiries. Experience the difference of our high-quality chains for your material handling needs.

Q&A (Frequently Asked Questions)

Q: Can the FV140SS Stainless Steel Scraper Chain be used in high-temperature environments?

A: Yes, the FV140SS chain is designed to withstand high temperatures and maintain its performance and structural integrity.

Q: Are the stainless steel scraper chains suitable for both horizontal and inclined material handling?

A: Absolutely, the FV140SS Stainless Steel Scraper Chain is versatile and can be used in both horizontal and inclined material handling applications.

Q: Do you provide installation assistance for the FV140SS Stainless Steel Scraper Chain?

A: While we do not provide on-site installation services, our technical support team is available to provide guidance and assistance during the installation process.

Edited by Zqq.

Specific Applications of FV140SS Stainless Steel Scraper Chain:

- Conveyor systems: The FV140SS chain is widely used in conveyor systems for efficient material transportation.

- Bulk material handling: It is suitable for handling bulk materials such as grains, coal, and minerals.

- Construction sites: The chain is commonly used in construction sites for material handling and transportation.

- Mining industry: It finds applications in mining operations for moving heavy loads and materials.

Why Choose FV140SS Stainless Steel Scraper Chain for Construction Material Handling?

The FV140SS Stainless Steel Scraper Chain offers various advantages that make it the ideal choice for construction material handling:

- High wear resistance: The chain’s stainless steel composition provides excellent wear resistance, ensuring a longer service life.

- Corrosion protection: The stainless steel material is highly resistant to corrosion, making it suitable for demanding environments.

- Efficient material handling: The chain’s design allows for smooth and efficient material transport, enhancing overall productivity.

- Reduced downtime: The chain’s durability and minimal maintenance requirements contribute to reduced downtime and increased operational efficiency.

- Safe operation: With its anti-slip properties and high heat resistance, the chain ensures a safe working environment for operators.

Common Fault Analysis, Diagnosis, and Maintenance

1. Fault: Chain elongation

Diagnostic steps: Check for excessive wear on the chain links and sprockets. Measure the chain’s pitch length to determine if it has elongated beyond the recommended tolerance.

Maintenance recommendation: Replace the elongated chain links and sprockets with new ones to ensure proper functioning and prevent further damage.

2. Fault: Chain jamming

Diagnostic steps: Inspect the chain for any foreign objects or debris that may be causing the jamming. Check the alignment of the chain and sprockets.

Maintenance recommendation: Remove any obstructions and ensure proper alignment of the chain and sprockets. Lubricate the chain if necessary to improve its performance.

3. Fault: Chain corrosion

Diagnostic steps: Examine the chain for signs of rust or corrosion. Determine the cause of corrosion, such as exposure to moisture or chemicals.

Maintenance recommendation: Clean the chain thoroughly and apply anti-corrosion coatings or lubricants to protect it from further corrosion. Regularly inspect and maintain the chain to prevent future corrosion.

Choosing and Customizing the Perfect Stainless Steel Scraper Chain

When selecting or customizing a stainless steel scraper chain, consider the following parameters and practical conditions:

- Load capacity: Determine the maximum load the chain will be subjected to in your specific application.

- Operating environment: Consider the temperature, humidity, and presence of corrosive substances in the operating environment.

- Chain pitch and width: Select the appropriate chain pitch and width based on your equipment’s requirements.

- Attachment type: Choose the suitable attachment type for your application, such as extended pins or flights.

- Customization options: If standard chains do not meet your needs, inquire about customization options such as special coatings or materials.

Stainless Steel Sprockets for Scraper Chains

The FV140SS Stainless Steel Scraper Chain and stainless steel sprockets are essential components that complement each other and play vital roles in material handling systems. The sprockets feature precise tooth profiles designed to match the FV140SS chain, ensuring smooth and reliable operation.

Our company also offers a wide range of stainless steel sprockets that are compatible with the FV140SS Stainless Steel Scraper Chain. These sprockets undergo rigorous quality control to ensure their compatibility and performance.

Recommendation and Company Advantages

We highly recommend our FV140SS Stainless Steel Scraper Chains for your construction material handling needs. Here are the advantages of choosing our product:

- Superior quality: Our chains are manufactured using the highest quality stainless steel, guaranteeing their durability and performance.

- Customization options: We offer customization services to meet your specific requirements, ensuring a perfect fit for your application.

- Competitive pricing: Our chains are competitively priced, offering excellent value for money.

- Reliable customer support: Our dedicated customer support team is available to assist you with any inquiries or concerns regarding our products.

- Fast and efficient delivery: We prioritize prompt delivery to ensure your construction projects stay on schedule.

Explore our FV140SS Stainless Steel Scraper Chains today and contact us for purchasing inquiries. Unlock the potential of your material handling operations with our high-quality products.

Q&A (Frequently Asked Questions)

Q: Can the FV140SS Stainless Steel Scraper Chain be used in high-temperature environments?

A: Yes, the FV140SS chain is designed to withstand high temperatures and maintain its performance and structural integrity.

Q: Are the stainless steel scraper chains suitable for both horizontal and inclined material handling?

A: Absolutely, the FV140SS Stainless Steel Scraper Chain is versatile and can be used in both horizontal and inclined material handling applications.

Q: Do you provide installation assistance for the FV140SS Stainless Steel Scraper Chain?

A: While we do not provide on-site installation services, our technical support team is available to provide guidance and assistance during the installation process.

Edited by Zqq.