Introduction

In the field of intercontinental ballistic missile defense, the FV250SS Stainless Steel Scraper Chain plays a crucial role in ensuring the smooth and efficient operation of the defense system. With its exceptional strength, durability, and innovative design, this scraper chain is specifically engineered to withstand the demanding conditions and rigorous requirements of missile defense applications.

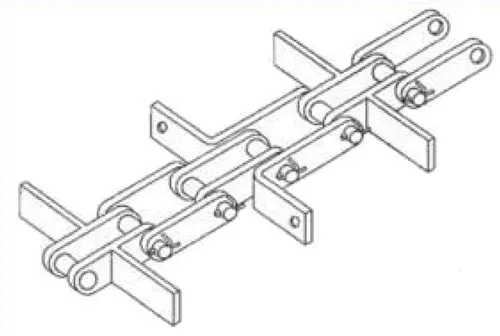

Understanding the Structure of FV250SS Stainless Steel Scraper Chain

The FV250SS Stainless Steel Scraper Chain is meticulously designed with a complex arrangement of various components, each serving a specific purpose to enhance its performance. The chain is composed of high-quality stainless steel links, meticulously interconnected to create a robust and reliable chain system. The structure of the scraper chain promotes enhanced flexibility, allowing it to adapt to different operating conditions with exceptional precision and reliability.

Applications of FV250SS Stainless Steel Scraper Chain

The FV250SS Stainless Steel Scraper Chain finds extensive applications in various critical areas of intercontinental ballistic missile defense. Some key applications of this chain include:

- Missile silo door opening and closing mechanisms

- Navigation and guidance systems

- Launch pad equipment

- Maintenance and inspection operations

- Security and surveillance systems

Each of these applications requires the FV250SS Stainless Steel Scraper Chain to perform critical functions, ensuring the smooth and efficient operation of the intercontinental ballistic missile defense system.

Why Choose FV250SS Stainless Steel Scraper Chain for Intercontinental Ballistic Missile Defense

The FV250SS Stainless Steel Scraper Chain offers numerous advantages and benefits that make it the ideal choice for intercontinental ballistic missile defense applications. Some key reasons to choose this chain include:

- Exceptional corrosion resistance: The stainless steel construction of the chain provides superior resistance to corrosion, ensuring its longevity even in harsh environments.

- High tensile strength: The FV250SS chain offers exceptional tensile strength, allowing it to withstand heavy loads and intense operating conditions.

- Precision engineering: The chain is meticulously engineered to provide precise and reliable performance, even in the most demanding applications.

- Low maintenance requirements: The FV250SS chain requires minimal maintenance, reducing downtime and ensuring uninterrupted operation.

- Enhanced durability: With its robust construction and high-quality materials, the chain exhibits exceptional durability, offering a long service life.

Common Fault Analysis, Diagnostic Steps, and Maintenance Recommendations

While the FV250SS Stainless Steel Scraper Chain is designed to withstand demanding conditions, it is crucial to be aware of potential faults that may arise. Here are some common fault phenomena, diagnostic steps, and maintenance recommendations:

- Fault Phenomena: Increased noise during operation

- Diagnostic Steps: Inspect the chain for signs of wear or damage. Check the alignment of sprockets and ensure proper lubrication.

- Maintenance Recommendations: Replace worn-out or damaged chain components. Adjust sprocket alignment and lubricate the chain regularly.

- Fault Phenomena: Chain elongation

- Diagnostic Steps: Measure the chain’s overall length and compare it to the manufacturer’s specifications. Inspect the links for signs of wear.

- Maintenance Recommendations: Replace the chain if it has exceeded the maximum allowable elongation. Regularly monitor and adjust tension to prevent further elongation.

- Fault Phenomena: Chain jamming

- Diagnostic Steps: Inspect the chain for foreign objects or debris. Check the alignment of sprockets and ensure smooth operation.

- Maintenance Recommendations: Remove any obstructions and clean the chain thoroughly. Adjust sprocket alignment and ensure proper lubrication.

Choosing and Customizing the Right Stainless Steel Scraper Chain

When selecting or customizing a stainless steel scraper chain for specific applications, several parameters and real-world conditions need to be considered. Here are some key factors to keep in mind:

- Operating temperature range: Ensure the chain can withstand the temperature variations encountered during missile defense operations.

- Chemical compatibility: Consider the presence of corrosive substances and select a chain that is resistant to such chemicals.

- Load capacity: Determine the maximum load the chain will experience and choose a chain with an appropriate weight-bearing capacity.

- Environmental conditions: Assess factors such as humidity, dust, and exposure to outdoor elements to select a chain that can withstand these conditions.

- System requirements: Consider the specific requirements of the missile defense system and choose a chain that meets those criteria.

Stainless Steel Sprockets for Scraper Chains

The FV250SS Stainless Steel Scraper Chain and stainless steel sprockets complement each other, forming a vital system for intercontinental ballistic missile defense. The sprockets are designed to precisely engage with the scraper chain, ensuring efficient power transmission and smooth operation.

At our company, we offer a wide range of compatible sprockets that are specifically engineered to work seamlessly with the FV250SS Stainless Steel Scraper Chain. These sprockets are manufactured with the same level of precision and attention to detail, guaranteeing optimal performance and longevity.

Our Recommendations and Company Advantages

We highly recommend our FV250SS Stainless Steel Scraper Chain for intercontinental ballistic missile defense applications. Here are five key reasons to choose our product and work with our company:

- Exceptional quality: Our stainless steel scraper chains are manufactured using the highest quality materials and undergo rigorous testing to ensure outstanding performance.

- Customization options: We offer customization services to tailor the chain to specific requirements, ensuring a perfect fit for any application.

- Reliable and timely delivery: We pride ourselves on our prompt and reliable delivery service, ensuring our customers receive their orders on time.

- Expert technical support: Our team of experienced professionals is available to provide technical assistance and guidance throughout the entire process.

- Competitive pricing: We offer competitive pricing without compromising on the quality of our products, providing excellent value for our customers.

We encourage our customers to explore the benefits of our FV250SS Stainless Steel Scraper Chain and contact us for any inquiries or to make a purchase. Our dedicated team will be delighted to assist you and ensure your satisfaction.

Q&A Section

Q: Can the FV250SS Stainless Steel Scraper Chain be used in extreme temperature conditions?

A: Yes, the FV250SS chain is specifically designed to withstand a wide range of temperature variations, making it suitable for extreme temperature conditions encountered in intercontinental ballistic missile defense applications.

Q: How often should the FV250SS Stainless Steel Scraper Chain be lubricated?

A: The lubrication frequency depends on the operating conditions and the manufacturer’s recommendations. However, it is generally advised to lubricate the chain regularly to ensure optimal performance and extend its service life.

Q: Can the FV250SS Stainless Steel Scraper Chain be repaired if it gets damaged?

A: Minor damages on the chain can often be repaired by replacing the affected links or components. However, it is recommended to consult a professional technician for a thorough assessment and to determine the best course of action.

Edited by Zqq.