The Importance of FV250SS Stainless Steel Scraper Chain

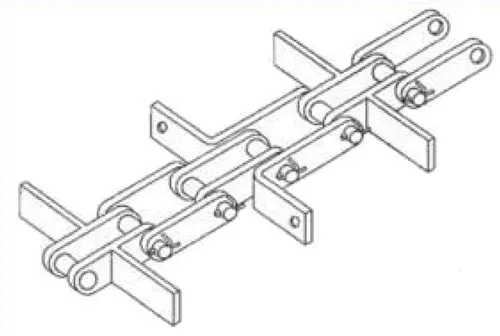

In large scale renewable energy projects, the FV250SS Stainless Steel Scraper Chain plays a crucial role in ensuring efficient and reliable operation. This chain is specifically designed to withstand the harsh conditions and heavy loads encountered in these projects. Its superior strength and durability make it an ideal choice for applications that demand high performance and long service life.

Application Scenarios of FV250SS Stainless Steel Scraper Chain

1. Wind Turbine Power Transmission System

The FV250SS Stainless Steel Scraper Chain is extensively used in wind turbine power transmission systems. Its high load-bearing capacity and corrosion resistance make it suitable for transferring power from the turbine to the generator. Additionally, its low maintenance requirements and long lifespan contribute to the overall reliability of the system.

2. Solar Panel Tracking System

In solar panel tracking systems, the FV250SS Stainless Steel Scraper Chain is employed to adjust the position of the panels for maximum sunlight exposure. Its precise and smooth operation ensures accurate tracking, enhancing the efficiency of solar energy collection. The chain’s resistance to environmental factors such as dust, heat, and moisture makes it an excellent choice for this application.

3. Hydroelectric Power Generation

Hydroelectric power plants utilize the FV250SS Stainless Steel Scraper Chain in various stages of power generation, including water intake, turbine operation, and dam maintenance. The chain’s robust construction and resistance to abrasion enable it to withstand the extreme forces and harsh conditions present in hydroelectric environments.

4. Biomass Conversion Systems

In biomass conversion systems, the FV250SS Stainless Steel Scraper Chain is used to transport biomass materials, such as wood chips or agricultural waste, through the conversion process. The chain’s ability to handle heavy loads and resist corrosion from biomass materials makes it an essential component of these systems.

5. Geothermal Energy Extraction

Geothermal energy extraction involves drilling deep into the earth to access the geothermal reservoirs. The FV250SS Stainless Steel Scraper Chain is utilized in the drilling equipment, providing reliable and efficient power transmission. Its resistance to extreme temperatures and aggressive chemicals ensures optimal performance in this demanding application.

Why Choose FV250SS Stainless Steel Scraper Chain for Large Scale Renewable Energy Projects

1. Superior Corrosion Resistance: The FV250SS Stainless Steel Scraper Chain is highly resistant to corrosion, ensuring its longevity in challenging environments.

2. High Strength and Durability: This chain is designed to withstand heavy loads and harsh operating conditions, providing reliable performance and extended service life.

3. Precise and Smooth Operation: The FV250SS Stainless Steel Scraper Chain offers precise and smooth operation, contributing to the overall efficiency of renewable energy systems.

4. Low Maintenance Requirements: Minimal maintenance is required for this chain, reducing downtime and overall operating costs.

5. Customizable Options: Our company offers a range of customization options to meet specific project requirements, ensuring optimal performance and compatibility.

Frequent Fault Phenomena, Diagnosis, and Maintenance of FV250SS Stainless Steel Scraper Chain

Frequent Fault Phenomena

– Abnormal chain wear and elongation

– Chain jamming or skipping

– Excessive noise during operation

– Chain corrosion and rust

Diagnosis and Troubleshooting Steps

– Regularly inspect the chain for signs of wear, elongation, or corrosion.

– Lubricate the chain according to manufacturer recommendations.

– Check for any misalignment or improper tensioning of the chain.

– Clean the chain and remove any debris or foreign particles that may cause jamming.

Maintenance and Replacement Suggestions

– Replace the chain if significant wear, elongation, or corrosion is detected.

– Properly lubricate the chain at regular intervals to minimize friction and wear.

– Ensure proper alignment and tensioning of the chain to prevent skipping or jamming.

– Use corrosion-resistant coatings or materials to protect the chain from environmental factors.

How to Choose or Customize the Suitable Stainless Steel Scraper Chain

Considerations for Choosing the Chain

– Load capacity requirements

– Environmental conditions (temperature, moisture, chemicals)

– Chain speed and power transmission efficiency

– Chain pitch and configuration

Detailed Explanations

– Assess the maximum load the chain needs to handle and select a chain with appropriate strength and load capacity.

– Consider the operating environment and choose a chain material that can withstand the temperature, moisture, and chemicals present.

– Determine the required chain speed and select a chain that can maintain optimal power transmission efficiency at that speed.

– Choose the appropriate chain pitch and configuration based on the specific requirements of the application.

Stainless Steel Sprockets for Scraper Chains

The FV250SS Stainless Steel Scraper Chain and stainless steel sprockets are integral components that work together to ensure smooth and efficient power transmission in large scale renewable energy projects. The sprockets provide the necessary engagement and drive for the scraper chain, ensuring precise movement and reliable operation.

Our company offers a wide range of stainless steel sprockets specifically designed to complement the FV250SS Stainless Steel Scraper Chain. These sprockets are manufactured with the same high-quality materials and precision engineering as our chains, ensuring optimal compatibility and performance. We are proud to provide a complete solution of scraper chains and sprockets for your renewable energy projects.

Recommendation: FV250SS Stainless Steel Scraper Chains

If you are looking for a reliable and durable solution for your large scale renewable energy projects, we highly recommend our FV250SS Stainless Steel Scraper Chains. Our chains are specifically designed to meet the demanding requirements of these projects and offer numerous advantages:

1. Superior Corrosion Resistance: The stainless steel construction ensures excellent resistance to corrosion, extending the lifespan of the chains.

2. High Load-Bearing Capacity: Our chains can handle heavy loads without compromising performance or safety.

3. Low Maintenance Requirements: Minimal maintenance is required, reducing downtime and operational costs.

4. Customizable Options: We offer customization options to meet specific project requirements.

5. Reliable Performance: Our chains are engineered for precise operation and long service life, ensuring continuous and efficient performance in renewable energy applications.

We encourage you to explore the benefits of our FV250SS Stainless Steel Scraper Chains and contact us to discuss your specific project needs. We are here to provide you with high-quality products and exceptional service.

Q&A Section

Q: Can the FV250SS Stainless Steel Scraper Chain be used in extreme temperature conditions?

A: Yes, the FV250SS Stainless Steel Scraper Chain is designed to withstand extreme temperatures, making it suitable for various industrial applications.

Q: How often should the FV250SS Stainless Steel Scraper Chain be lubricated?

A: The lubrication frequency depends on the specific operating conditions and manufacturer recommendations. Regular lubrication is crucial to ensure optimal performance and extend the chain’s lifespan.

Q: Can the FV250SS Stainless Steel Scraper Chain withstand exposure to harsh chemicals?

A: Yes, the FV250SS Stainless Steel Scraper Chain is resistant to corrosion from chemicals, making it suitable for applications where exposure to such substances is expected.

Edited by Zqq.