Introduction

The FV250SS Stainless Steel Scraper Chain is a high-quality chain specifically designed for Supranational Manufacturing Facilities. This chain is widely used in various industrial applications, including conveyor systems, material handling, and production lines. Its exceptional durability and excellent performance make it an ideal choice for demanding manufacturing environments.

1. Chain Structure and Features

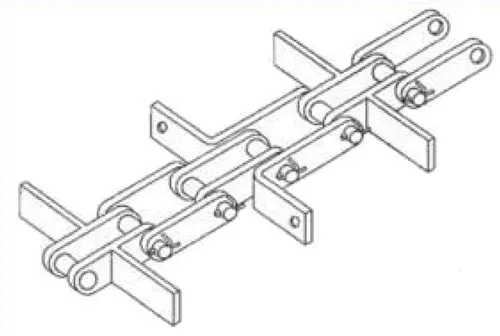

The FV250SS Stainless Steel Scraper Chain features a robust and corrosion-resistant construction, ensuring its longevity even in harsh operating conditions. Its unique design incorporates precision-engineered scraper plates that effectively remove bulk materials from conveyors. Additionally, the chain is equipped with specially designed pins and bushes to minimize wear and maximize efficiency.

2. Application Areas

The FV250SS Stainless Steel Scraper Chain finds wide applications in Supranational Manufacturing Facilities. Some key areas where this chain is extensively used include:

- 1. Scraping and conveying of raw materials

- 2. Waste management systems

- 3. Industrial furnaces and kilns

- 4. Food processing plants

- 5. Automotive manufacturing

In these applications, the FV250SS Stainless Steel Scraper Chain plays a crucial role in ensuring efficient and reliable material handling, reducing downtime, and improving overall productivity.

Why Choose FV250SS Stainless Steel Scraper Chain for Supranational Manufacturing Facilities

1. Exceptional Corrosion Resistance: The stainless steel construction of the FV250SS Scraper Chain makes it highly resistant to corrosive environments, ensuring long-lasting performance.

2. High Load Capacity: This chain is designed to withstand heavy loads and provide reliable operation even in demanding manufacturing settings.

3. Precision Engineering: The scraper plates and specially designed pins and bushes ensure precise material scraping and smooth operation, minimizing the risk of jams or breakdowns.

4. Low Maintenance: The FV250SS Scraper Chain requires minimal maintenance, reducing downtime and overall operating costs.

5. Customization Options: Our company offers a range of customization options to meet specific requirements, including chain length, attachments, and surface treatments.

Common Fault Analysis and Maintenance for FV250SS Stainless Steel Scraper Chain

1. Fault Phenomenon Analysis:

– Chain skipping or jumping

– Excessive noise during operation

– Uneven wear of scraper plates

2. Fault Diagnosis Steps:

– Check chain tension and adjust if necessary

– Inspect sprockets for wear and replace if needed

– Lubricate the chain regularly to reduce friction

3. Maintenance and Replacement Recommendations:

– Clean the chain regularly to remove debris and prevent buildup

– Replace worn or damaged scraper plates promptly

– Regularly inspect and replace pins and bushes to maintain optimal performance

Choosing and Customizing the Right Stainless Steel Scraper Chain

When selecting or customizing a stainless steel scraper chain, consider the following parameters and practical conditions:

1. Chain Length: Determine the required chain length based on the specific conveyor system and material handling requirements.

2. Attachment Types: Choose the appropriate attachments for specific material scraping and conveying needs, such as scraper plates, cleats, or buckets.

3. Surface Treatment: Select the suitable surface treatment for corrosion resistance, such as zinc plating, nickel plating, or stainless steel coating.

4. Operating Environment: Consider the temperature, humidity, and chemical exposure levels in the manufacturing facility to ensure the chain’s compatibility and longevity.

5. Load Capacity: Assess the maximum load requirements to ensure the chain can handle the intended workload without performance issues.

Stainless Steel Sprockets for Scraper Chains

The FV250SS Stainless Steel Scraper Chain and Stainless Steel Sprockets are essential components that work together seamlessly. The sprockets provide the necessary engagement and drive for the scraper chain, ensuring smooth and efficient material handling. Our company offers a wide range of sprockets specifically designed to complement the FV250SS Scraper Chain.

Recommendation and Our Advantages

We highly recommend our FV250SS Stainless Steel Scraper Chain for Supranational Manufacturing Facilities due to the following advantages:

1. Superior Material Quality: Our scraper chains are made from high-grade stainless steel, ensuring exceptional durability and corrosion resistance.

2. Customization Options: We offer a wide range of customization options to meet specific application requirements, guaranteeing optimal performance.

3. Expert Engineering: Our scraper chains are precision-engineered for reliable and efficient material handling, minimizing downtime and increasing productivity.

4. Competitive Pricing: We provide cost-effective solutions without compromising on quality, offering excellent value for money.

5. Prompt Customer Support: Our dedicated customer support team is always available to assist with any inquiries, ensuring a smooth purchasing experience.

We encourage you to explore the benefits of our FV250SS Stainless Steel Scraper Chain and contact us for further information or to place an order.

Q&A (Frequently Asked Questions)

Q1: Can the FV250SS Stainless Steel Scraper Chain be used in high-temperature environments?

A1: Yes, the FV250SS Scraper Chain is designed to withstand high temperatures, making it suitable for various industrial applications, including those with elevated heat levels.

Q2: Can the scraper plates be easily replaced?

A2: Yes, the scraper plates of the FV250SS Scraper Chain can be easily replaced as they are designed for quick and hassle-free maintenance.

Q3: Is it possible to customize the chain’s attachment spacing?

A3: Yes, our company offers customization options, including attachment spacing, to ensure the chain meets your specific requirements.

Edited by Zqq.